Sorting systems for the careful transport and distribution of general cargo

Our focus is on the economical, safe and secure transport of parcels and general cargo from incoming to outgoing goods. Our products are driveless conveyor elements which enable the space-saving, vertical transport of your conveying range.

And to ensure this, we develop spiral chutes, transfer chutes and terminal stations for sorting systems used by parcel services, postal companies and online shops that we supply worldwide. Plus, our portfolio also extends to the outfitting of airport and port logistics.

The systems implemented can be operated either manually or automatically and can also be put to use as buffer storage.

Suitable interfaces ensure seamless integration of sensors and electronics into our conveyor elements.

Our systems are extremely durable and are characterised by their low-wear and low-maintenance. In terms of appearance and design, we can coat our systems in any RAL colour and, if desired, in several colours as well.

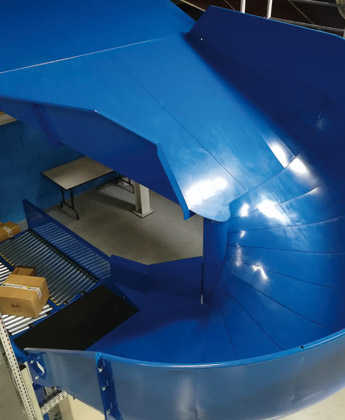

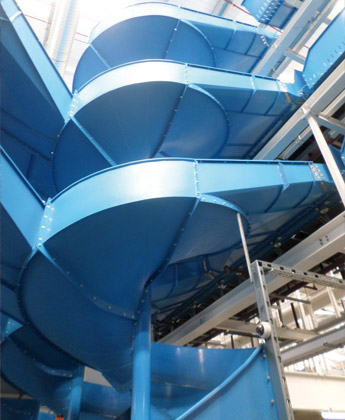

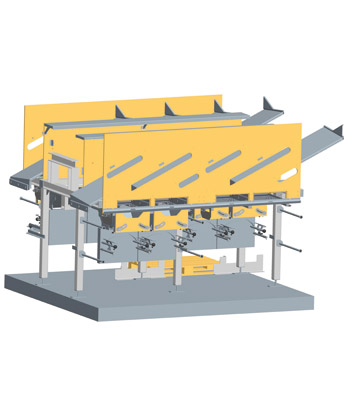

Spiral chutes are used to bridge relatively large height differences in confined spaces with the option of several feeds, arranged opposite or one above the other.

Our spiral chutes are developed, designed and manufactured individually according to your specific needs. The conveying height and direction can be varied by a modular design, and the coil diameter and pitch as well as the dimensions of the inputs and outputs are variable. The active sliding surface is pressed three-dimensionally with gentle transitions for particularly smooth and noiseless transport of packaged goods. Under certain conditions, it is also possible to implement a spiral chute with a double spiral.

Our chutes are made of steel or stainless steel. Depending on the design, they are coated with a special lubricant varnish and can be provided with an anti-drumming compound for noise insulation on request. For special applications, it is possible to combine a steel frame with a plastic lining.

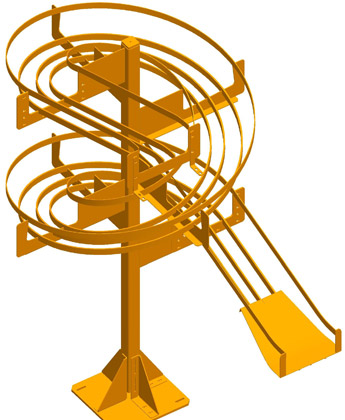

Roller Spiral are used for the horizontal transport of packaged goods with a slight gradient. We use them to supplement our chutes and terminals as supplying or discharging elements. At the end of a transport section, they can also be put to use as a buffer section.

Our Roller Spiral are designed application specifically and are fully variable in all dimensions. Brake rollers can be added to regulate the speed.

Transfer chutes are used for the transport of packaged goods subject to slight height differences and changes in direction. These chutes are frequently put to use as interfaces between two conveyor lines.

We design them according to your requirements in straight, curved or combined design, whereby the length and width of the transfer chutes can be varied. All transfer chutes have smooth transitions for particularly gentle and noiseless transport of packaged goods.

This special chute design is used for conveying uniform transport containers.

Due to the design of the chute, the containers are guided laterally and transported lengthwise. We produce this type of chute in straight, curved or coiled form.

The container chute can be made of flat or round steel, depending on the specific requirements. Special plastic sliding strips are used as gliding partners for transporting the containers.

Buffer terminals are used to temporarily store a larger volume of packaged goods without necessitating continuous manual unloading. This means that there is no need for an operator to be present at all times when filling the terminal station.

Our buffer chutes are designed to ensure that largest possible volumes can be stored without being subjected to damage. During removal, the following packaged goods start up automatically, so that even the very last packages can be removed ergonomically.

The so-called cascade chute is a special buffer terminal design to further increase storage volumes. Furthermore, horizontal removal tables are implemented to conclude the conveyor technology process.

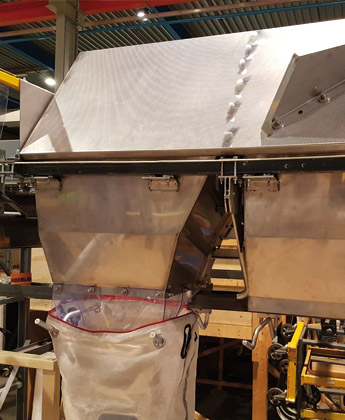

Small-sort terminals are conveyor elements for the targeted collection of small to very small packaged goods (e.g. letters, bags, polybags, book consignments) in higher-level conveyors such as sacks, cartons or containers. We design these individually according to your specific application.

Frequent variants of these terminals consist of hoppers for gentle and product-friendly input of the packaged goods to be conveyed and of suspension or storage options for ergonomic positioning of the receiving conveyors.

We manufacture our small-sort terminals from steel or stainless steel, often in combination with either wood or plastic.

SATISFIED CUSTOMERS

BULK MATERIAL TECHNOLOGY – SPIRAL CHUTES

Spiral chutes for bulk material are used to transport loose bulk material downwards across great height differences. A controlled and grain-friendly transport is decisive in this process.

We design bulk material chutes for various areas of applications. In the field of mining and surface mining for the transportation of ores, stones, sand and coal, we develop chutes in such a way that they consist of a load-bearing basic structure and a screwed, replaceable wear lining. Self-supporting basic structures without wear lining are designed for light, small-grained bulk materials. A further design variant of the bulk material chute is characterised by an inward opening construction, which is commonly used for silo filling.

We manufacture the bulk material chutes from steel or stainless steel, the basic structures can be galvanised. The wear lining can consist of steel sheets of different degrees of hardness. For the food industry, we use abrasion-resistant stainless steel sheets.