7 steps to completion of the project

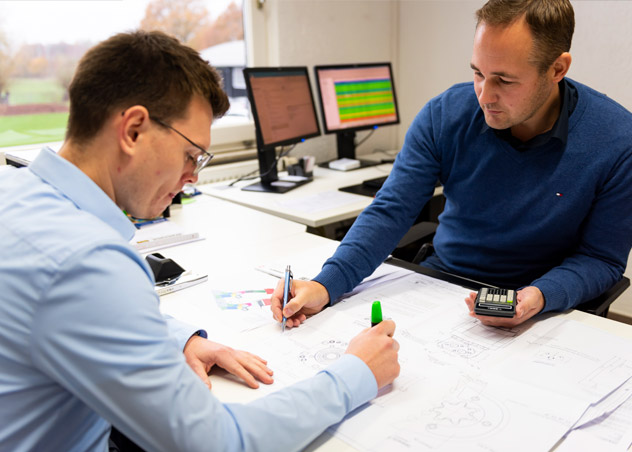

Consulting |

On the basis of your enquiry, we intensively examine project-relevant information. Together, on the basis of joint personal consultations, we develop a technically optimal solution in order to select a product most suited to your application.

Should we identify potential savings on the basis of our experience, we would be pleased to suggest improvements in the interest of our clients. Throughout the entire course of the project, a project manager is always available to provide advice as a permanent point of contact.

Development |

On the one hand, our technical competence results from our many years of experience in mechanical engineering and plant construction and, on the other hand, from our innovative strength, which we prove time and again.

We look at problems spanning various departments from different perspectives in order to arrive at optimised solutions, especially for very complex requirements. The diversity of our products is an expression of the breadth of our existing know-how.

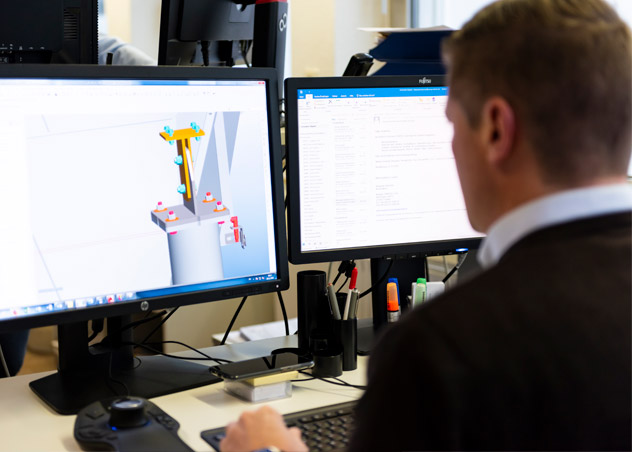

Design |

Regardless of whether for series production or for complex projects: Our design department is an essential component of our successful project management process. Using the very latest 2D and 3D CAD software, our experienced team of engineers designs the products as the basis for reliable order processing.

The CAD data is continuously shared with you for optimum ‘interfacing’ clarity.

|

|

Manufacturing |

More than 55 years of experience combined with a young, qualified team provide the basis for the high-quality manufacture of our products.

In our spacious production facilities, equipped with state-of-the-art machinery, tools and ergonomic workstations, we are in a position to carry out a wide range of machining operations safely and efficiently.

This guarantees highest delivery reliability and outstanding quality.

|

|

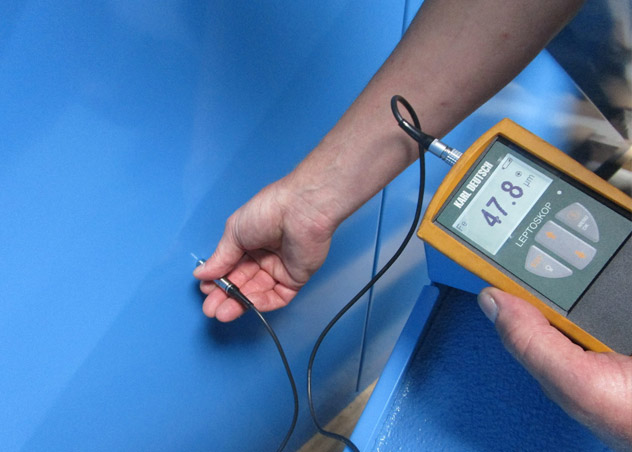

Quality assurance |

Each of our individual parts is checked for functionality and dimensional accuracy. Even in series production, we do not reduce our quality checks to random samples, but check each individual component in accordance with our standards defined by a QMS to ensure consistently high quality.

In the case of new developments, prototypes are always manufactured and checked for functionality and optimisation potential in our test hall.

Before equipment or machines leave our factory, they are assembled in our factory according to your specifications. The assembly activities are carefully monitored and permanently controlled.

Assembly |

The high quality of our products results in a repeatability of our components to ensure smooth and cost-effective on-site assembly.

In addition, as early as the development phase, we focus on designing products that are as easy to assemble as possible in order to ensure rapid assembly progress.

Our supervisors have extensive experience in optimising the installation of the plants and in supervising installation teams.

Close contact with your contact partners throughout the entire duration of the project enables us to deliver in a time and space-optimised manner.

|

|

Support |

Once the project has been successfully completed, we will of course continue to be at your disposal. We would be pleased to receive your feedback so that we can draw conclusions about potential improvements and develop solutions together.

Our goal is a long-term and trusting partnership with you!